Cement shaped skylines, yet its shadow grew heavy. Builders now eye a different path that uses ordinary earth, careful compaction, and reclaimed tubes instead of high-emission binders. A lab team proposes a binder-free material for low-rise walls that cuts costs and slashes emissions. The recipe looks local and the tools stay light. The result promises durability without the usual footprint that follows concrete and steel across long, fragile supply lines.

From rammed earth roots to a modern system

Rammed earth has endured for millennia because compacted soil resists weather, stores heat, and ages gracefully. Modern practice often adds cement to meet codes, which cancels many climate benefits. The RMIT team revisits the core recipe and redesigns the formwork instead of the mix, deliberately, for safety and reliability.

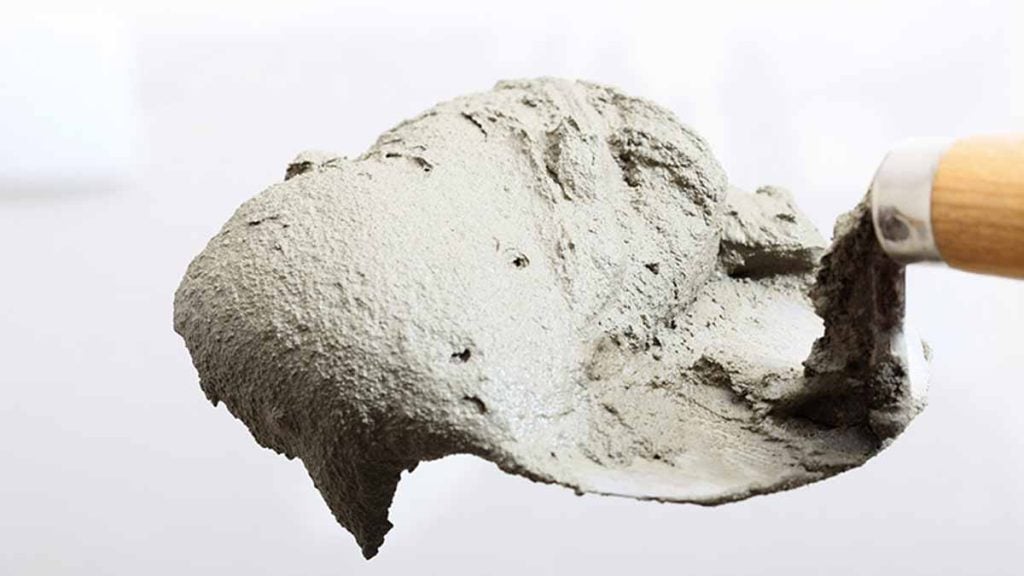

They pack a moist soil blend inside sturdy, recycled cardboard tubes. The tubes confine and stabilize the soil while curing, reduce shrinkage, and let crews stack units as they build. Because the tubes replace energy-heavy binders, the wall gains strength with minimal emissions. Crews handle the material using simple tools.

Tests target low-rise construction where thick walls excel at carrying weight. The approach favors hot regions, where high thermal mass smooths daily swings and eases cooling demand. Each part is easy to source and reuse. Supply risks shrink while site waste declines steadily and predictably over time.

How the material forms strength without cement

The soil is compacted in thin lifts inside each tube, which acts like permanent formwork and lateral bracing. Compression locks particles together, while the cardboard prevents dilation under load. This synergy yields a wall that carries vertical forces and resists cracking, with the material remaining fully binder free.

Traditional practice often adds Portland cement to stabilize soil. That step increases emissions and cost, yet thick walls already carry large loads by geometry. The team reframed the problem: keep thickness, remove binders, and rely on confinement. It preserves strength while avoiding the carbon and curing delays.

Engineers control performance by choosing tube diameter and thickness. These variables tune stiffness and buckling resistance, so designers can match loads and spans. For applications that need higher capacity, a variant introduces carbon fiber within the earth core. Tests reached strengths comparable to high-grade concrete under controlled conditions.

Real-world uses, thermal comfort, and waste reduction

The wall system suits hot, dry regions where resources are scarce and transport is costly. High thermal mass dampens daytime peaks and stores coolness into the evening, which reduces cooling loads. Because local soil is the main input, crews can fabricate modules directly at the site today.

Recycling gains stack up. Australia sends more than 2.2 million tons of paper and cardboard to landfill each year. That stream could feed tubing for this approach. The material also takes apart cleanly, so offcuts return to reuse, and components avoid the long tail of demolition waste.

Project teams still need good soils, moisture control, and quality checks. Clear specifications cover compaction energy, lift height, and tube alignment, while simple jigs keep tolerances tight. Because walls are thick, openings need thoughtful detailing. Lintels, sills, and joints should distribute loads safely and evenly for long service.

Costs, carbon math, and scaling the material

Cement drives nearly eight percent of yearly global carbon dioxide, according to data cited by the U.S. EPA. Removing cement from the wall erases most embodied emissions. RMIT’s analysis estimates a quarter of concrete’s footprint for comparable roles. Production cost drops to less than one third for typical modules.

Savings come from simple ingredients, short supply lines, and low power needs. Crews mix soil and water on site and compact in place, so hauling of heavy goods drops. Because components are recyclable and reusable, the material keeps waste low and helps projects meet circular-economy targets on tight budgets.

Those numbers matter in a $500 billion construction market as governments push for lower emissions. The system looks ready for piloting because it skips rare inputs and complex tooling. Teams can tune tube thickness and standardize details. They can also share data in open, peer-reviewed case studies.

Roadblocks, pilots, and what comes next

RMIT’s team is pursuing industrial partners to trial the system in the field. Early pilots can validate loads, durability, and constructability under different climates. Because the method uses common tools, training emphasizes compaction practice and moisture control. Consistent formwork keeps results reliable, repeatable, and easy to audit.

Adoption will still face codes, insurance, and perception. Authorities need clear test results, while builders want simple details for corners, cores, and connections. The material joins a wider push toward nature-based building, alongside hemp-lime and mycelium composites. It stands out for straightforward logistics and timely delivery for builders.

Limits exist. Flooding risk calls for raised plinths and robust caps. In very cold regions, extra protection and hybrid solutions may serve better. Yet the premise remains powerful. Rethink inputs, reuse waste, shorten transport, and deliver safe shelter without complex factories or fragile supply chains over time.

Why this simple approach could change how we build everywhere

The promise here is not flashy technology, but fit-for-purpose design that matches real needs. Swapping binders for confinement and reusing waste trims cost and emissions without complex factories. Local crews can shape modules on site and keep supply lines short. Policymakers can align codes with evidence from pilots and peer-reviewed data. If results hold, the material could deliver sturdy walls and steady comfort. It offers a grounded way to build with what communities already have.